Choosing the right acrylic sheet is critical for the success of your project, whether it's for sleek retail displays, durable signage, or precision machinery parts. Not all acrylic is created equal, and selecting a substandard product can lead to yellowing, cracking, and a poor finish that tarnishes your final product.

As a leading supplier, we want to empower you with knowledge. Here are 5 key metrics to help you distinguish premium acrylic from the inferior competition.

1. Thickness Tolerance (The Benchmark of Precision)

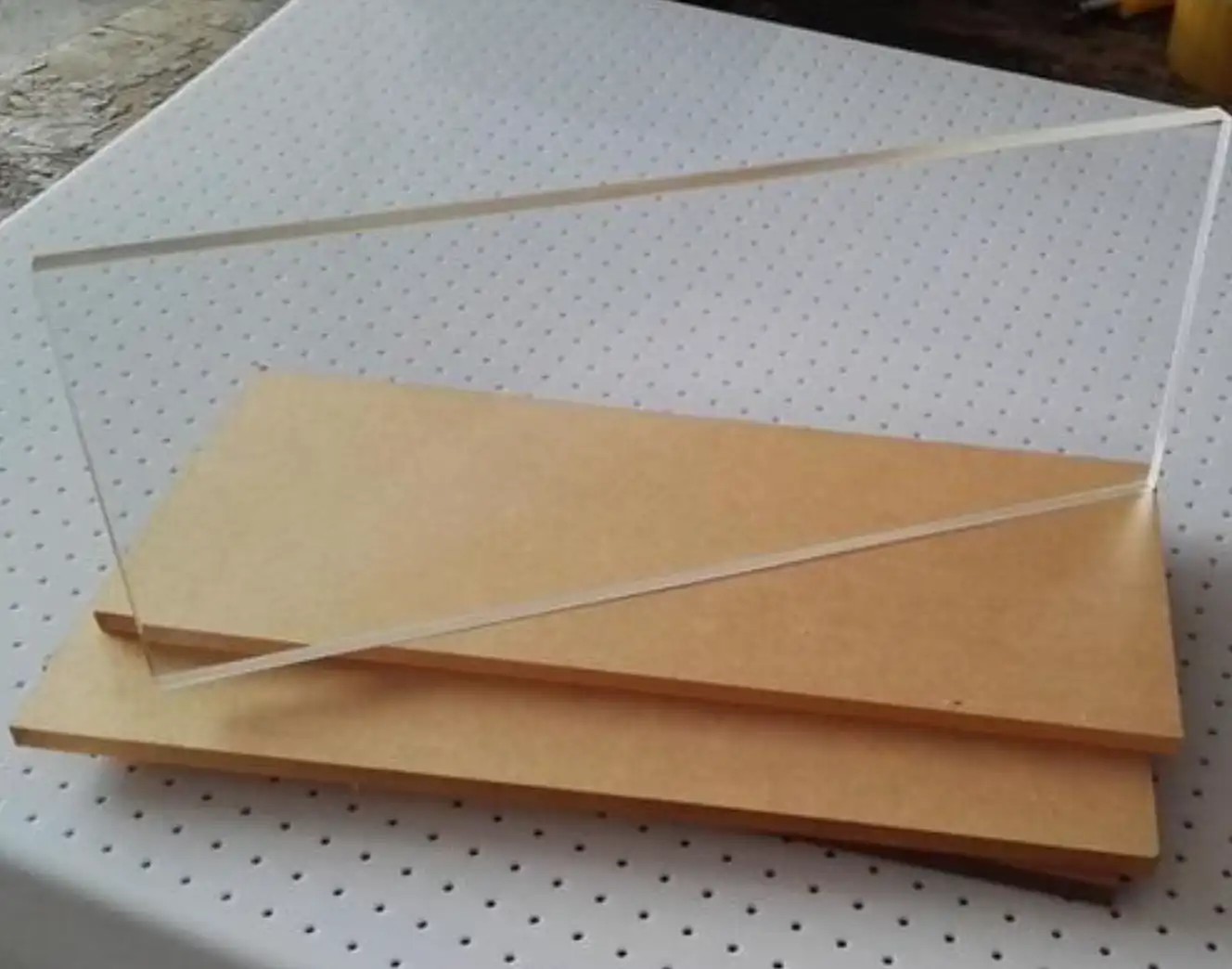

What it is: The consistency of the sheet's thickness across its entire surface. It's measured in millimeters (mm) and a tight tolerance (e.g., ±0.1mm) is a sign of superior manufacturing. Why it matters: Inconsistent thickness can cause optical distortion in displays, fitting issues in fabrication, and structural weaknesses. Poor tolerance is a telltale sign of a low-quality extrusion or casting process. Ask your supplier: "What is your guaranteed thickness tolerance for [X]mm sheet?" Premium suppliers will have a precise, documented answer.

2. Surface Hardness & Scratch Resistance (The Shield of Durability)

What it is: Acrylic's ability to resist scratches and abrasions, often measured on the Rockwell M scale. Why it matters: A harder surface maintains its pristine, glossy appearance during handling, installation, and throughout its lifespan. Low-quality acrylic scratches easily, looking old and worn before its time. Quick tip: High-quality acrylic will have a hard, glass-like feel. You can ask for material data sheets (MDS) to compare hardness ratings.

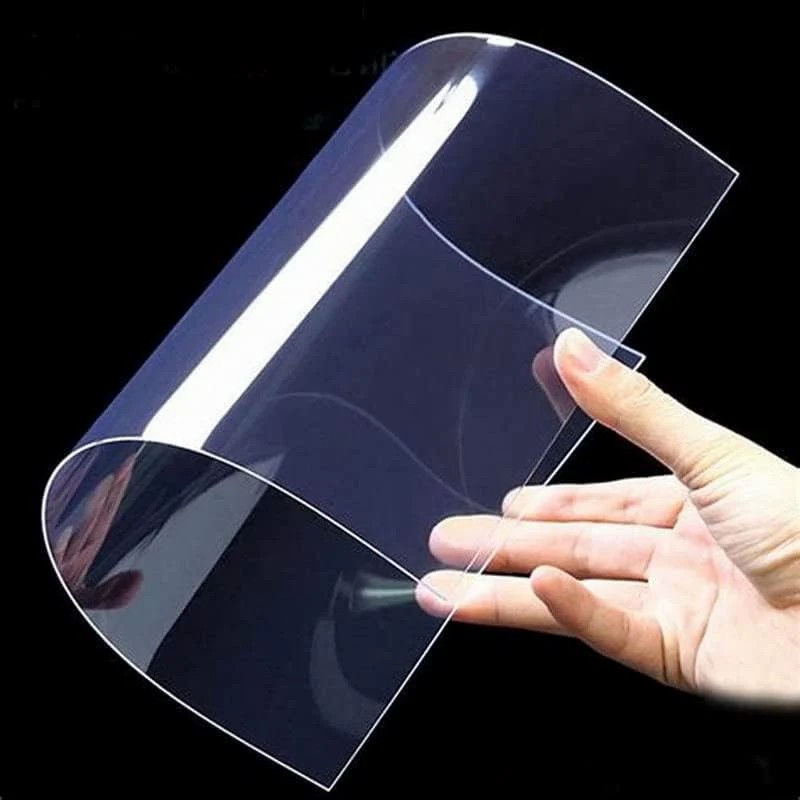

3. Light Transmittance & Purity (The Hallmark of Clarity)

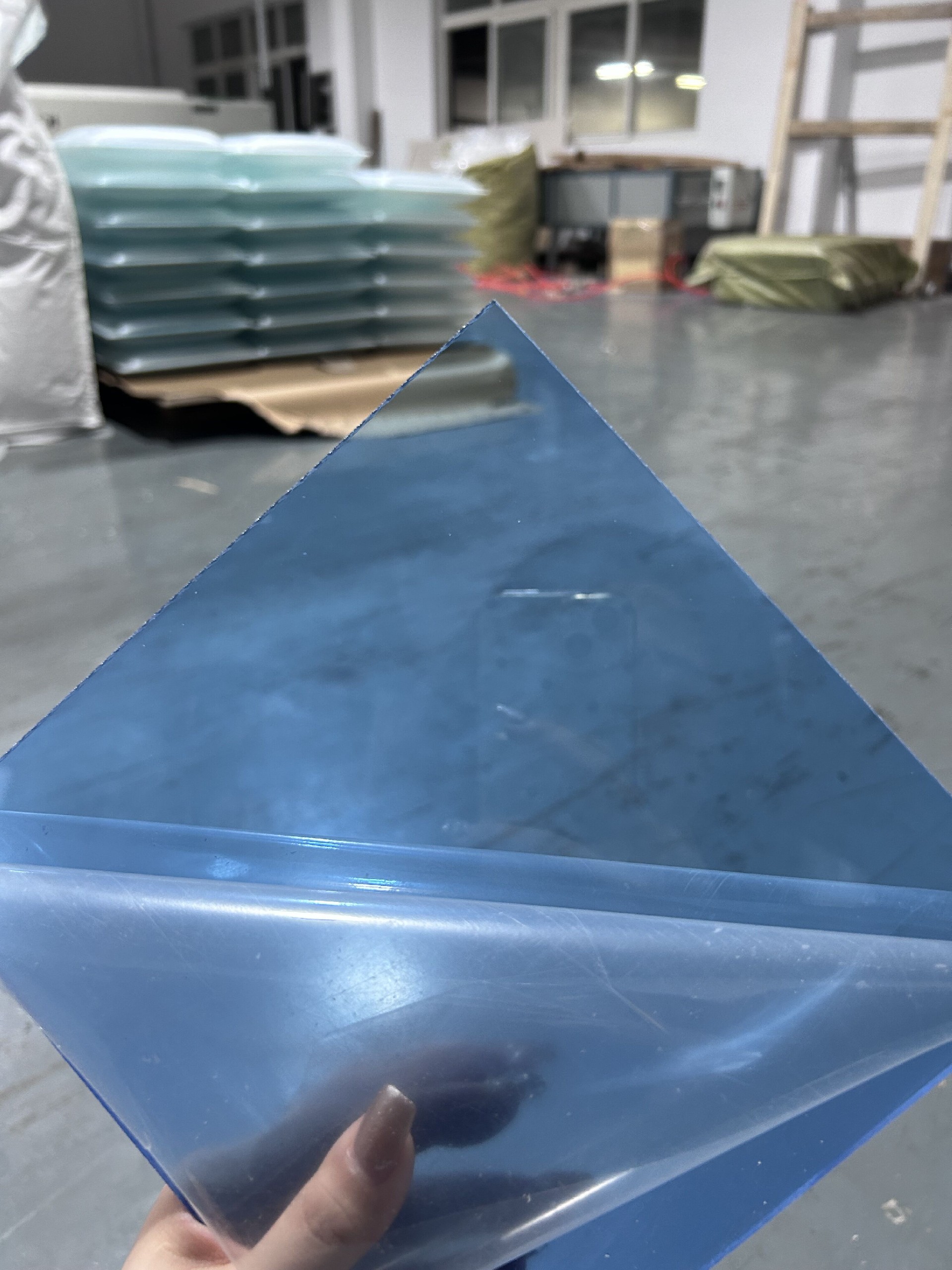

What it is: The percentage of light that passes through the material without being scattered or absorbed. Top-tier extruded acrylic offers around 92% light transmittance, rivaling glass. Why it matters: For applications like light guides, displays, and protective barriers, maximum clarity is non-negotiable. Lower quality sheets with impurities or recycled content can appear hazy or have a slight blue or yellow tint. Look for: Crystal-clear, optically pure sheets with no visible haze or discoloration.

4. Impact Strength & Weatherability (The Test of Time)

What it is: The material's resistance to impact (less brittle than glass) and its ability to withstand UV radiation and environmental elements without degrading. Why it matters: Outdoor signage must resist yellowing and embrittlement from the sun. Interior pieces must withstand accidental impacts. UV-stabilized acrylic ensures long-term performance. Ask your supplier: "Is this material UV-stabilized for outdoor use?" and "What is its impact resistance rating?"

5. Raw Material Source: Virgin vs. Regrind (The Foundation of Quality)

What it is: Virgin acrylic is made from pure, first-use PMMA pellets. Regrind (or recycled content) comes from reprocessed plastic. Why it matters: While some regrind can be acceptable for lower-grade applications, high percentages significantly reduce the sheet's UV resistance, yellowing stability, and overall mechanical properties. Premium sheets use 100% virgin raw material for guaranteed performance. This is often the most important differentiator. Always insist on knowing the material composition.

Become a Smarter Buyer

Armed with these five metrics, you can move beyond just comparing price per sheet. You can evaluate true value, reduce project failures, and ensure your final product looks professional and lasts longer.

At Aludream Plastics , we don't just sell acrylic sheets; we provide certainty. Every sheet that leaves our facility is backed by strict quality controls and transparent specifications on these exact metrics.

What’s your biggest challenge when sourcing acrylic? Share your experiences in the comments below.

👉 Follow our page for more insights on material selection and industry applications. 👉 Request a Free Sample of our premium acrylic to see and test the difference for yourself. (visit our website:www.aludreamplastics.com)